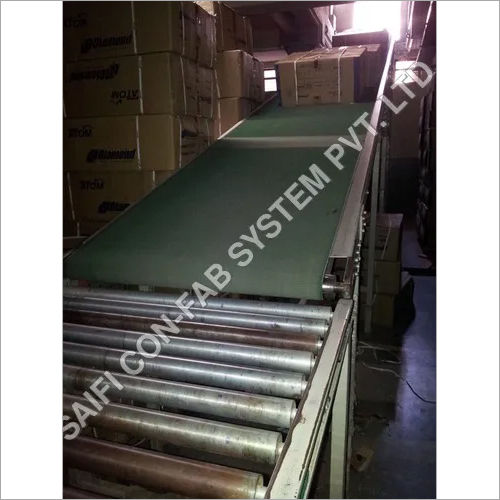

Hinged Belt Conveyor

300000 INR/Unit

Product Details:

- Thickness Belt thickness: 2 mm to 6 mm

- Surface Finish Powder coated / Painted

- Features High durability, easy maintenance, modular design, side guides for spillage control

- Power Source Electric motor

- Belt Type Hinged steel belt

- Material Mild steel (MS) or stainless steel (SS)

- Type Hinged Belt Conveyor

- Click to View more

X

Hinged Belt Conveyor Price And Quantity

- 1 Unit

- 300000 INR/Unit

Hinged Belt Conveyor Product Specifications

- Mild steel (MS) or stainless steel (SS)

- Powder coated / Painted

- Robust fabricated steel frame

- Hinged Belt Conveyor

- No

- 220V / 380V

- No

- Belt thickness: 2 mm to 6 mm

- Metal chips, scrap handling, stamping operations, bulk material transfer

- Electric motor

- Yes

- Variable, up to 30 m/min

- 1.5 kW to 5 kW

- No

- Hinged steel belt

- Up to 2000 kg

- High durability, easy maintenance, modular design, side guides for spillage control

- Corrosion resistant

Hinged Belt Conveyor Trade Information

- 1 Unit Per Week

- 1 - 4 Week

Product Description

Due to the technological aptitude of our knowledgeable professionals, we have been able to manufacture, export and supply a quality assortment of Hinged Belt Conveyor. This conveyor used in industries for handling chips, scraps, forgings etc. It is manufactured at our latest manufacturing unit by utilizing premium quality raw materials with the aid of modern technology in adherence with current industry standards. Apart from this, provided Hinged Belt Conveyor can be availed from us in various specifications at market leading prices.

Features:

- Precise dimensions

- Fine finish

- Sturdily built

- Easy to install

Robust Structure and Flexible Installation

This conveyor is built with a strong fabricated steel frame and utilizes a hinged steel belt, available in mild steel or stainless steel. Users can install it with either floor mounting or pit mounting options, making it adaptable to various workshop layouts and space constraints. Its modular design supports easy integration and extension as production needs grow.

High Performance and Low Maintenance

The conveyor delivers high durability and reliability, thanks to its corrosion-resistant surface finish and robust drive. Simple access panels and easy lubrication points ensure routine maintenance is straightforward, minimizing operational downtime. The conveyor operates efficiently within a wide temperature range, from -20C to 80C.

FAQs of Hinged Belt Conveyor:

Q: How is the Hinged Belt Conveyor installed and what mounting options are available?

A: The Hinged Belt Conveyor can be installed either on the factory floor or mounted in a pit, depending on operational requirements and available space. This flexibility allows for adaptation to various production environments.Q: What materials and bulk items can this conveyor handle effectively?

A: Designed for tough applications, the conveyor efficiently transports metal chips, bulk scrap, stamping waste, and other heavy materials. The hinged steel belt ensures durability and control over challenging loads, making it ideal for metalworking industries.Q: When should I perform routine maintenance, and what procedures are involved?

A: Routine maintenance should be conducted periodically, typically based on operational intensity. Maintenance actions include lubricating accessible points, inspecting belt integrity, and checking for safe operation of emergency stop buttons and side covers. The conveyors simple access panels make this process quick and convenient.Q: Where is this conveyor most commonly used?

A: It is widely used in manufacturing plants, stamping facilities, scrap handling operations, and bulk material transfer sites. Its adaptability and robust design serve various sectors across India, including export and supply businesses.Q: What safety features are included to ensure safe operation?

A: Safety is prioritized with emergency stop buttons, protected side covers to prevent accidental contact, and modular side guides to control material spillage, adhering to industry safety standards for operator protection.Q: How does the variable speed benefit production processes?

A: Variable speed control, up to 30 m/min, provides operational flexibility, allowing adjustment according to load type and transfer rate requirements. This enhances process efficiency and helps optimize workflow within diverse production setups.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Belt Conveyors' category

We want inquires from NORTH INDIA.

|

SAIFI CON-FAB SYSTEM PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |